產(chǎn)品中心

PRODUCT

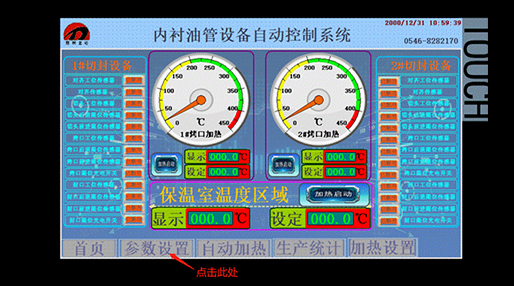

Control System for Lined Tubing Production Line

Time:2024-04-29

Click:

Detailed introduction

Control System for Lined Tubing Production Line

The production line adopts PLC integrated intelligent control, and the control system mainly includes three aspects: software system, hardware system, sensors, and actuators.

The Software System includes:The PLC program is the core of the automated production line control, responsible for processing control logic and instructions. The computer control software coordinates and manages various aspects of the automated production line. The communication software is mainly responsible for data transmission and communication with various external devices.

Hardware System mainly includes equipment such as PLC controllers, frequency converters, and robot controllers. They control various aspects of the production line to ensure its smooth operation.

Sensors and Actuators is responsible for sensing the environment and manipulating objects. Sensors detect various parameters and states of objects, such as position, speed, temperature, etc. Actuators control the movement of various machines and equipment on the production line based on control instructions.

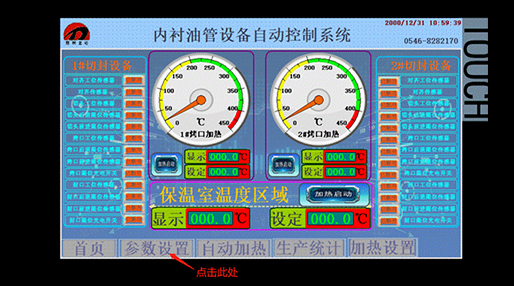

The production line adopts PLC integrated intelligent control, and the control system mainly includes three aspects: software system, hardware system, sensors, and actuators.

The Software System includes:The PLC program is the core of the automated production line control, responsible for processing control logic and instructions. The computer control software coordinates and manages various aspects of the automated production line. The communication software is mainly responsible for data transmission and communication with various external devices.

Hardware System mainly includes equipment such as PLC controllers, frequency converters, and robot controllers. They control various aspects of the production line to ensure its smooth operation.

Sensors and Actuators is responsible for sensing the environment and manipulating objects. Sensors detect various parameters and states of objects, such as position, speed, temperature, etc. Actuators control the movement of various machines and equipment on the production line based on control instructions.